brinell hardness test conclusion|hardness tester lab report pdf : wholesale Conclusion. In a nutshell, the Brinell hardness test records the diameter and depth of the indentation caused by a ball-shaped indenter, with the indenter pressed into a material’s .

WEB25 de dez. de 2023 · Top 10 Best RTP Slots: Our Ranking. Want play the best RTP online slots? Here’s out list of the 10 highest RTP slots with a summary of what to expect from each of the slot games. Ugga Bugga – .

{plog:ftitle_list}

Resultado da 30 de jan. de 2021 · https://store.steampowered.com/app/1468720/Ultimate_Epic_Battle_Simulator_2/ 欢迎来到终极史诗战斗模拟器2,世界上最荒谬和疯狂的战斗模拟器!在屏幕上与成千上万,甚至数百万的角色创造令人流泪的战斗!. 创世神即时战略 .

Conclusion: In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and . Conclusion. The Brinell hardness method is a simple, fast, and reliable method for measuring the hardness of various materials. It does not require any special preparation of . The ASTM’s Brinell hardness test standard is used by alloy and metal suppliers and users, and it’s a basic requirement for all hardness testing equipment. This kind of .CONCLUSION. Despite having other tests to compute the hardness of a material, Brinell Hardness test was used in this lab. After calculating the hardness number, it is found that the average number for steel is 95 and that .

The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .

Conclusion. In a nutshell, the Brinell hardness test records the diameter and depth of the indentation caused by a ball-shaped indenter, with the indenter pressed into a material’s .It is: BHN = 2 P / (π D (D – (D2 – d2)1/2)) Where: BHN = Brinell hardness number. P = the load on the indenting tool (kg) D = the diameter of steel ball (mm) d = measure diameter at the rim .

Dry and wet method laser particle size Analyzer store

The Brinell hardness test is a commonly used hardness testing method that measures the hardness of materials. It does so by pressing a hard ball indenter into the surface of the material under a specified load and .

Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison .The Brinell hardness test method is used to calculate the hardness of the metal object. It is also referred to in ASTM E10. . Conclusion. In this blog, we have explained that Brinell hardness is therefore among the oldest methods that have been used to test metals and alloys and theoretically is the most perfect way to do hardness testing. We .6 Using your own word, explain the Brinell Hardness Test? 7 CONCLUSION - Make an intelligent conclusion of your experiment base on data and **discussion. Give examples in industrial application; Is this result a kind of .

Sample Calculations: Brinell Hardness Test (1020 Steel) Brinell Hardness Number, BHN D = 10-mm P = 3000 kg d = 4.37-mm BHN = 190 Tensile Strength = BHN x 500 = 190 x 500 = 95000 psi Rockwell Hardness Test (1020 Steel) .

For Brinell hardness test. The hardness of materials are test by pressing a steel ball or tungsten carbide ball for a time of 10 to 15 seconds into the surface of specimen by a standard load F [kgf]. After that, the diameter of the indentation d [mm] is measured when the load is removed. . Conclusion. By using HRD indenter it is shown that . Brinell testing, indicated by “BHN” (Brinell Hardness Number) is somewhat opposite to the Knoop and Vickers tests. In the Brinell hardness test a spherical indenter having a diameter of 10mm is used with an impressive 3,000 kg (~6,600 lbs.). 6. General types of hardness testing... Current practice in USA divides hardness testing into two categories: Macrohardness: Refers to testing with applied loads on the indenter of more than 1 kg and material being tested are tools, dies and sheet material in the heavier gages(in large scale) Microhardness: Refers to testing with applied loads are 1 kg or .With a variety of options, from Rockwell and Brinell to Vickers and Knoop test blocks, all calibration and verification requirements of hardness testing machines can be efficiently and reliably met. Certification according to international standards such as ISO and ASTM supports compliance with high-quality standards and ensures precise test .

Brinell hardness test is used to determine the hardness of the metal through its ability to avoid permanent indentation deformation. This test is performed under special standardized conditions by creating penetration by an indenter in a spherical shape. . Conclusion. To conclude, the most important step in any hardness testing method is the . CONCLUSION AND RECOMMENDATION From the experiment, the hardness testing is to measure of hardness of material’s resistance to localized plastic deformation. This experiment also experienced students to be able to perform the hardness using two type of machine with specific of hardness testing but in this experiment we just used the Rockwell .

In conclusion, the Brinell hardness test methods have specimen requirements that contribute immensely to the accuracy of the test. These requirements include surface preparations like grinding and machining, which are often minimal due to the large size of the material and the loads applied. Also, the minimum thickness requirements specified by .Concluding a hardness test using a popular method like the Brinell hardness test requires measuring the indentation left on the material surface by the load applied. Though several other hardness testing methods are available, the Brinell hardness test and how to read and represent its values are why we’ve written this guide. This Brinell hardness testing machine can be used for the Vicker’s hardness test also. Conclusion. We have discussed how the test is conducted and the principle of the Brinell hardness test. and also we have discussed the precautions that we have to take before we begin the test.Scope of Portable Hardness Testers. The standard test method ASTM E110-14 is offered in determining Rockwell and Brinell hardness of metallic materials by a portable hardness tester. The test is essential when samples are too bulky or heavy to be assessed by traditional, immobile instruments. This standard provides procedures for testing .

Conclusion . ASTM E10 is an essential standard in materials testing to date. The standard operational guidelines for Brinell hardness testers ensure that this kind of test provides consistent and accurate hardness test results within .Brinell hardness test is slower to perform with the estimated time of 30 to 60 seconds, while Rockwell hardness is fast enough to show results in 10-15 seconds. . Conclusion. Hardness tests of metals are essential to manufacture reliable big machines and automobiles. The hardness test should be first selected according to the needs of the .While the Brinell hardness test is widely used in the industry today, some features which make it unique are worth mentioning. Firstly, it enjoyed standardization before any other method was standardized which also accounts for why it is widely used. . Conclusion. To wrap up, knowing the best-suited hardness test of the three, Rockwell .

Double Column Tensile Tester store

The Brinell Hardness Test is one of the popular methods used to measure the hardness of metals. This method is used to inspect materials that have a rough surface, and other methods cannot be used. . Conclusion. The Brinell hardness test was developed by the American Henry Brinell, who created the first tester in 1873. This is a widely .

The Brinell hardness test method consists of indenting the test material with a 10 mm diameter hardened steel or carbide ball subjected to a load of 3000 kg. For softer materials the load can be reduced to 1500 kg or 500 kg to avoid excessive indentation. The full load is normally applied for 10 to 15 seconds in the case of iron and steel and .

4. Sun-Tec Corporation Headquarters: Michigan, USA Description: Sun-Tec Corporation is a US based company that was created in the year 1931. Their specialization is in technical services and hardness testing for machines. Their products range include Rockwell hardness testing, Vickers or Knoop hardness testing, Brinell hardness testers, Compression instruments, .Rockwell hardness test is applied with the carbide balls to test softer materials such as construction steels or brass because if you test soft material with diamond cones, it could cause very deep penetration into the material which will go .Macro Brinell hardness test measurement is calculated by the formula in which the applied test force (kilograms) is divided by the surface area of the developed indentation (square millimeters). The final value is called a pressure measurement, but it has no unit. . Conclusion. Micro hardness testing method and Macro hardness testing method .

Digital Display Tensile Tester store

The data obtained by Brinell hardness test with the tungsten carbide ball “HBW” and non – standardized hardened steel ball “HBS” measured by 8 appraisers were compared by Youden plot, MSA, analysis of uncertainty, t-test and analysis of variance (ANOVA). . Deductions were made, conclusion derived from discussion of the analyzed .Electronic Brinell hardness tester; Digital Brinell hardness tester (touch screen) Visual Brinell hardness tester (touch screen) Fully automatic Brinell hardness tester; Brinell hardness image processing system; Vickers hardness tester seriesThe Brinell Hardness Test is one tool that can help you measure the hardness of metal samples because it measures the force required to deform one millimeter of metal into a two-millimeter diameter sphere. . Conclusion. In regards to zinc hardness testing, there are several tools that you can use to measure its hardness and understand it .

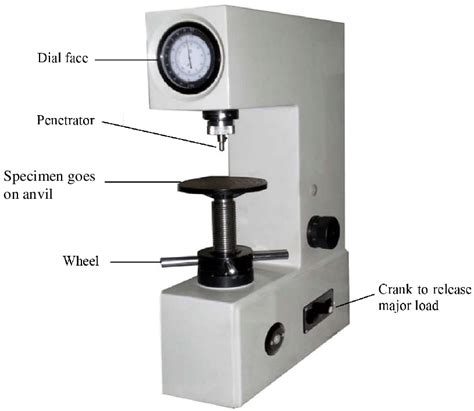

12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. Brass was tested in B scale, using a 1/16” ball as head and a 100 kg major load. Copper was tested in F scale, using a 1/16” ball as head and 60 kg major load.

The Brinell hardness test, which is relatively slower than other methods, can be used for microhardness and microhardness testing. This method can be used to test materials that have coarse or inhomogeneous surfaces that other methods cannot be used. . Conclusion. The Vickers method has higher accuracy than the Brinell method and can be used .

rockwell hardness tester procedure pdf

Watch Youjizz porn videos for free, here on Pornhub.com. Discover the growing collection of high quality Most Relevant XXX movies and clips. No other sex tube is more popular and features more Youjizz scenes than Pornhub! Browse through our impressive selection of porn videos in HD quality on any device you own.

brinell hardness test conclusion|hardness tester lab report pdf